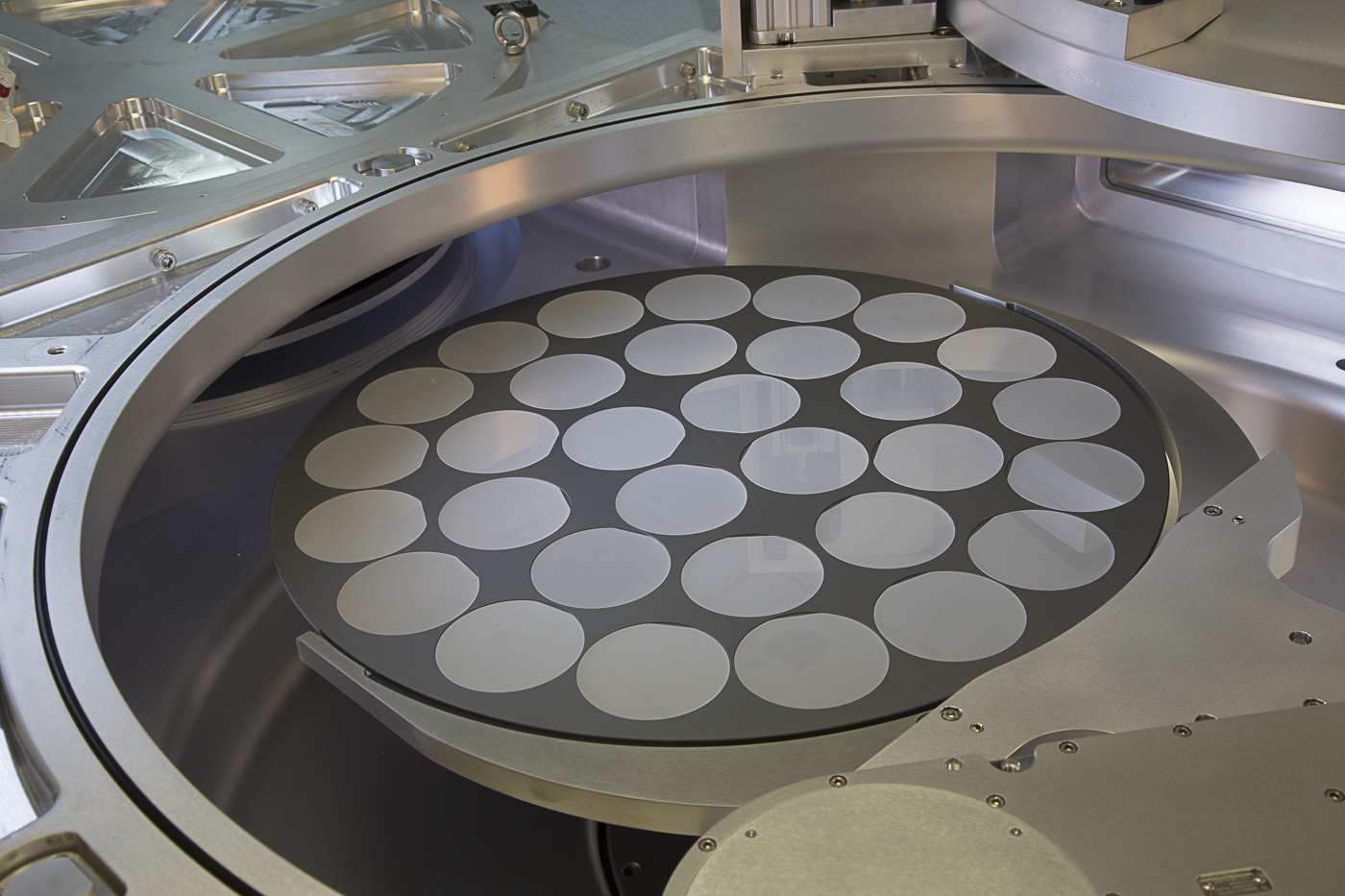

SiC Coated MOCVD Susceptor Market Overview

The SiC (Silicon Carbide) coated MOCVD (Metal Organic Chemical Vapor Deposition) susceptor market plays a critical role in the production of compound semiconductor materials used in various high-tech applications such as power electronics, LED lighting, and wireless communication devices. MOCVD is a key process in the fabrication of compound semiconductors, and the susceptor serves as a crucial component, facilitating the growth of high-quality semiconductor films. This comprehensive overview will explore various aspects of the SiC coated MOCVD susceptor market, including market dynamics, key players, technological advancements, growth drivers, challenges, and future prospects.

Market Dynamics

The SiC coated MOCVD susceptor market is influenced by several factors, including the increasing demand for compound semiconductor devices, advancements in MOCVD technology, the growing focus on energy efficiency, and regulatory initiatives promoting the adoption of clean energy solutions. The market is characterized by intense competition, rapid technological advancements, and a strong emphasis on product quality and performance.

Key market dynamics include:

- Growing Demand for Compound Semiconductors: Compound semiconductors such as gallium nitride (GaN), gallium arsenide (GaAs), and indium phosphide (InP) are essential materials for various advanced applications, including power electronics, RF devices, and optoelectronics. The increasing adoption of compound semiconductor devices drives the demand for MOCVD susceptor solutions capable of delivering high-quality epitaxial films.

- Advancements in MOCVD Technology: Continuous innovation in MOCVD equipment, processes, and materials is essential for meeting the evolving requirements of semiconductor manufacturers. SiC coated susceptor platforms offer several advantages, including enhanced thermal stability, improved film uniformity, reduced contamination, and prolonged equipment lifespan, contributing to the growth of the market.

- Focus on Energy Efficiency: Energy efficiency is a key consideration for semiconductor manufacturing facilities seeking to reduce operating costs, minimize environmental impact, and comply with regulatory requirements. SiC coated MOCVD susceptor solutions help improve process efficiency, reduce energy consumption, and enhance overall equipment performance, thereby supporting sustainability initiatives.

- Regulatory Initiatives: Government regulations aimed at reducing carbon emissions, promoting energy conservation, and accelerating the adoption of clean energy technologies drive investments in compound semiconductor research and development. SiC coated MOCVD susceptor solutions enable the production of high-performance semiconductor materials required for next-generation energy-efficient devices, aligning with regulatory goals.

Technological Advancements

- Advanced Coating Technologies: Advancements in coating materials and deposition techniques enable the deposition of high-quality SiC coatings on susceptor surfaces with precise control over thickness, uniformity, and adhesion. SiC coatings offer superior thermal stability, chemical resistance, and compatibility with compound semiconductor processes.

- Enhanced Thermal Management: SiC coated susceptor platforms provide improved thermal management capabilities, allowing for more efficient heat transfer and temperature control during epitaxial growth. Enhanced thermal stability minimizes temperature fluctuations, reduces thermal stress on substrates, and enhances film uniformity and quality.

- Reduced Contamination: SiC coatings on susceptor surfaces minimize contamination risks associated with metal susceptor materials, such as particulate generation, outgassing, and chemical reactions with process gases. Reduced contamination levels contribute to higher yield, improved device performance, and longer equipment uptime.

- Extended Equipment Lifespan: SiC coated susceptor platforms offer increased durability and resistance to wear, erosion, and chemical attack compared to traditional susceptor materials. Extended equipment lifespan reduces maintenance requirements, downtime, and overall cost of ownership for semiconductor manufacturers.

Receive the FREE Sample Report of SiC Coated MOCVD Susceptor Market Research Insights @ https://stringentdatalytics.com/sample-request/sic-coated-mocvd-susceptor-market/7945/

Market Segmentations:

Global SiC Coated MOCVD Susceptor Market: By Company

• Toyo Tanso

• SGL Carbon

• Tokai Carbon

• Mersen

• Bay Carbon

• CoorsTek

• Schunk Xycarb Technology

• ZhiCheng Semiconductor

Global SiC Coated MOCVD Susceptor Market: By Type

• GaN

• InP

• Other

Global SiC Coated MOCVD Susceptor Market: By Application

• LED Lighting

• Advanced Packaging and MEMS

• Semiconductors

• Others

Regional Analysis of Global SiC Coated MOCVD Susceptor Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global SiC Coated MOCVD Susceptor market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase SiC Coated MOCVD Susceptor Market Research Report @ https://stringentdatalytics.com/purchase/sic-coated-mocvd-susceptor-market/7945/

Growth Drivers

- Rising Demand for Compound Semiconductors: The increasing adoption of compound semiconductor devices in applications such as power electronics, LED lighting, and wireless communication drives the demand for high-performance epitaxial films produced using MOCVD technology and SiC coated susceptor platforms.

- Advancements in Semiconductor Manufacturing: Continuous advancements in semiconductor manufacturing processes, equipment, and materials drive the adoption of SiC coated MOCVD susceptor solutions capable of delivering superior film quality, process stability, and equipment reliability.

- Focus on Energy Efficiency and Sustainability: Semiconductor manufacturers prioritize energy-efficient processes, materials, and equipment to reduce operating costs, minimize environmental impact, and comply with regulatory requirements. SiC coated MOCVD susceptor solutions contribute to energy savings, process efficiency, and environmental sustainability.

- Expansion of Applications: The expansion of applications such as automotive electrification, 5G wireless networks, Internet of Things (IoT) devices, and renewable energy systems creates new opportunities for compound semiconductor technologies and SiC coated MOCVD susceptor solutions.

Challenges

- Cost Considerations: SiC coated susceptor solutions may involve higher initial costs compared to traditional susceptor materials, which can pose challenges for semiconductor manufacturers seeking to balance performance requirements with cost constraints.

- Technical Complexity: SiC coating processes require specialized equipment, expertise, and quality control measures to ensure uniformity, adhesion, and durability of coatings. Addressing technical challenges related to coating deposition, process optimization, and quality assurance is essential for achieving consistent performance.

- Supply Chain Risks: The availability and cost of raw materials, equipment components, and coating technologies may impact the supply chain for SiC coated MOCVD susceptor solutions. Managing supply chain risks, including disruptions, shortages, and price fluctuations, is critical for semiconductor manufacturers.

- Regulatory Compliance: SiC coated susceptor solutions must comply with regulatory requirements governing materials, emissions, and workplace safety. Adhering to environmental, health, and safety regulations, obtaining certifications, and addressing compliance challenges are important considerations for susceptor suppliers.

Future Prospects

The SiC coated MOCVD susceptor market is poised for significant growth in the coming years, driven by technological advancements, expanding applications, and increasing demand for compound semiconductor devices. Key future prospects include:

- Development of Advanced Coating Technologies: Continued research and development efforts focused on improving SiC coating technologies, including deposition methods, coating materials, and surface treatments, will drive enhancements in susceptor performance, durability, and reliability.

- Expansion into Emerging Markets: The adoption of compound semiconductor technologies is expected to expand into emerging markets such as automotive electrification, renewable energy, and advanced manufacturing, creating new opportunities for SiC coated MOCVD susceptor solutions.

- Integration of Smart Technologies: The integration of smart sensors, real-time monitoring systems, and predictive analytics within MOCVD equipment and susceptor platforms will enable proactive maintenance, process optimization, and quality control, enhancing overall equipment performance and productivity.

- Focus on Sustainability: Semiconductor manufacturers will continue to prioritize sustainability initiatives, including energy efficiency, waste reduction, and circular economy principles. SiC coated MOCVD susceptor solutions that contribute to energy savings, resource conservation, and environmental stewardship will gain traction in the market.

In conclusion, the SiC coated MOCVD susceptor market plays a vital role in enabling the production of high-quality compound semiconductor materials for various advanced applications. With advancements in coating technologies, thermal management, and process optimization, SiC coated susceptor solutions offer significant performance advantages over traditional susceptor materials. Addressing challenges related to cost, technical complexity, supply chain management, and regulatory compliance will be essential for sustainable growth and competitiveness in the dynamic and evolving semiconductor industry. Continued innovation, strategic partnerships, and market expansion efforts will drive the success of SiC coated MOCVD susceptor suppliers in the global marketplace.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Leave a Reply