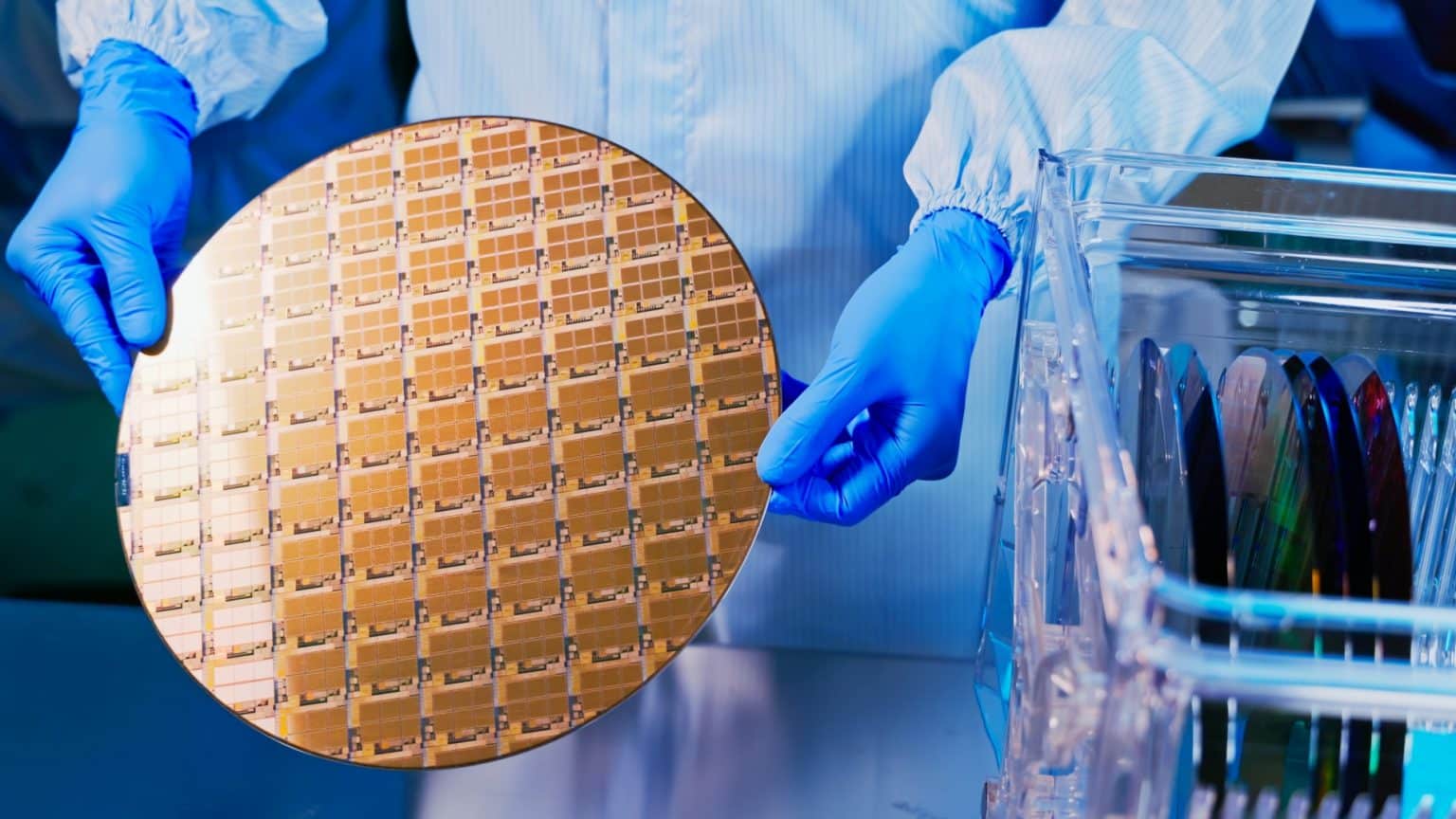

Introduction to Float Zone Wafers:

- High-Purity Manufacturing: Float Zone Wafers are meticulously produced through the float zone refining method, a high-purity manufacturing process known for its efficiency in removing impurities during crystal growth.

- Crystal Growth Control: The controlled solidification process ensures precise control over crystal growth, resulting in a silicon wafer with superior material characteristics.

- Unique Production Method: The float zone method distinguishes itself by allowing the silicon to float freely within the high-temperature zone, contributing to the elimination of unwanted impurities.

Purity and Quality:

- Virtually Impurity-Free: The float zone refining technique excels in creating wafers with minimal impurities, offering a crystal structure virtually free from contaminants such as metals and dopants.

- Enhanced Electrical Properties: Exceptional purity enhances the electrical properties of the wafers, making them ideal for applications demanding high performance and reliability.

- Reduced Crystal Defects: The method minimizes crystal defects, resulting in wafers with fewer dislocations and vacancies, positively impacting overall material quality.

Applications in the Semiconductor Industry:

- Foundation for Advanced Devices: Float Zone Wafers serve as the foundational material for the production of advanced semiconductor devices and integrated circuits, ensuring a reliable and high-performance base.

- Optimal Semiconductor Functionality: The high-purity silicon contributes to optimal semiconductor functionality, facilitating the efficient operation of transistors, diodes, and other semiconductor components.

- Process Compatibility: The wafers are compatible with cutting-edge semiconductor manufacturing processes, enabling the fabrication of devices with increasingly smaller dimensions and enhanced performance.

High-Temperature Applications:

- Thermal Stability: Float Zone Wafers exhibit superior thermal stability, making them well-suited for applications in high-temperature environments where other materials might degrade.

- Power Devices: These wafers are integral to the production of power devices that require stability and efficiency at elevated temperatures, contributing to advancements in energy technology.

- Thermally Demanding Environments: Industries such as aerospace, automotive, and power generation benefit from Float Zone Wafers in environments with extreme thermal conditions.

Photonics and Optoelectronics:

- Precision in Light Emission: The exceptional crystal quality of Float Zone Wafers is crucial for precision in light emission, making them preferred in the manufacturing of lasers where coherence and wavelength control are paramount.

- Photodetector Performance: Their application extends to photodetectors, ensuring high sensitivity and low noise levels due to the pure crystal structure, supporting advancements in imaging and sensing technologies.

- Reduced Scattering: Superior crystal clarity reduces scattering losses in optical components, enhancing the overall efficiency of photonic devices.

Research and Development Initiatives:

- Enhanced Float Zone Techniques: Ongoing R&D focuses on refining and enhancing the float zone refining technique to achieve even higher levels of material purity and crystal perfection.

- Material Characterization: Advanced material characterization techniques, including spectroscopy and imaging, contribute to a deeper understanding of the crystal structure, guiding improvements in the manufacturing process.

- Innovations in Crystal Growth: Researchers explore innovations in crystal growth control, investigating new methods to reduce defects and improve overall wafer quality.

Receive the FREE Sample Report of Float Zone Wafer Market Research Insights @ https://stringentdatalytics.com/sample-request/float-zone-wafer-market/7804/

Market Segmentations:

Global Float Zone Wafer Market: By Company

• WaferPro

• Shin-Etsu Chemical

• SUMCO CORPORATION

• Siltronic

• GlobalWafers

Global Float Zone Wafer Market: By Type

• 2 Inch

• 3 Inch

• 4 Inch

• 8 Inch

• 12 Inch

• Others

Global Float Zone Wafer Market: By Application

• Solar Chips

• RF Circuits

• Power Devices

• Others

Regional Analysis of Global Float Zone Wafer Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Float Zone Wafer market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Float Zone Wafer Market Research Report @ https://stringentdatalytics.com/purchase/float-zone-wafer-market/7804/

Market Growth Drivers:

- Consumer Electronics Demand: The increasing demand for high-performance consumer electronics, including smartphones, tablets, and laptops, is a major driver for the Float Zone Wafer market.

- 5G Technology Adoption: The widespread adoption of 5G technology, with its demand for high-frequency components, contributes to the growth of the market as Float Zone Wafers play a crucial role in enabling advanced semiconductor devices.

- Electric Vehicles and Renewable Energy: Growth in the electric vehicle market and renewable energy technologies further drives demand for Float Zone Wafers in power electronics and energy-efficient devices.

Global Market Presence:

- International Manufacturing Hubs: Key manufacturers and suppliers of Float Zone Wafers operate in international manufacturing hubs, providing a global supply chain to meet the diverse needs of semiconductor industries worldwide.

- Collaborative Supply Chains: Global partnerships and collaborative supply chains ensure a steady flow of high-quality Float Zone Wafers to semiconductor manufacturers, fostering a resilient market presence.

Emerging Technologies and Applications:

- Quantum Information Processing: Float Zone Wafers play a pivotal role in the development of materials for quantum information processing, where the precise control of material properties is essential for the creation of qubits and quantum gates.

- Advanced Sensor Technologies: In the realm of advanced sensor technologies, Float Zone Wafers contribute to the production of sensors with enhanced sensitivity and reduced noise, supporting applications in healthcare, environmental monitoring, and industrial automation.

Collaborations and Partnerships:

- Industry-Academia Collaboration: Collaborations between semiconductor manufacturers, academic institutions, and research centers foster innovation by combining industry expertise with cutting-edge research.

- Shared Research Facilities: Joint access to shared research facilities allows for the optimization of manufacturing processes, materials testing, and the development of new technologies, benefiting the entire industry.

- Knowledge Exchange: Collaborations facilitate knowledge exchange, enabling a faster implementation of advancements and improvements in Float Zone Wafer manufacturing.

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client’s needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Leave a Reply